Selected Products For Your Success

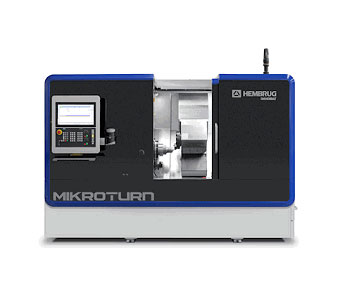

Hembrug

Specialist for Highprecision-Hardturning

Hembrug Machine Tools has been developing, building and selling the world’s most accurate hard-turning lathes under the name Mikroturn® for more than 50 years. With the Mikroturn® series, components with complex contours up to 1,500 mm in diameter and 70 HRC in thehighest precision class can be produced. The machines are completely oil-bearing so that the μm precision after 20 or 30 years is just as high.

Hembrug’s Mikroturn® hard lathes have a broad field of application and are used worldwide in

various precision industries such as the bearing and automotive industries. Hembrug offers 5

horizontal and 5 vertical versions of the machines.

The horizontal machines are suitable for small to medium workpieces up to a diameter of 600 mm and a weight of 300 kg. The vertical machines are suitable for large components up to a diameter of 1,500 mm and 2,000 kg in weight. The machines can also be equipped with automation, grinding or belt finishing capabilities.

The Hembrug head office with 70 employees is located in Haarlem-Netherlands. Hembrug also has a sales office in North America and works together with a variety of agents throughout

Info HEMBRUG

Hendrik Figeeweg 1a

NL-2031 BJ Haarlem

Tel. +31 23 512 4900-0

Fax +31 23 512 4901

Product Overview

Mikroturn 100 3rd Generation

Base made of natural granite

Hydrostatic slide and work spindle

Good thermal stability

Improved tool life

State-of-the-art Siemens 840D "solution line" control with 0.01μm resolution

Mikroturn 100 XLD

Base made of natural granite

Turning diameter up to 610mm

Hydrostatic slides and work spindle with 2000rpm

Workpiece weight up to 200kg

State-of-the-art Siemens 840D "solution line" control with 0.01μm resolution

Mikroturn 100 XLS

Base made of natural granite

Machining of workpieces with a length between centers of up to 1000mm and 240mm diameter!

Hydrostatic slides with linear motors

Reduction of cycle times

State-of-the-art Siemens 840D "solution line" control with 0.01μm resolution

Mikroturngrind 1000

Hard turning and fine grinding in one machine!

Base made of natural granite

Machining area 200x800mm between centers

Hydrostatic slide and work spindle

External and internal grinding