Selected Products For Your Success

Supfina

Solutions – Services – High Precision Abrasive Machining

With locations in Germany, the USA, and China, Supfina Grieshaber is one of the world’s leading manufacturers and solution providers of systems for high-precision abrasive machining

More than 200 qualified and highly specialized employees design and build machines and equipment for superfinishing, double-disk grinding, fine grinding, flat finishing, and edge preparation. We also specialize in automation solutions.

As a modern company, Supfina offers its customers integrated and innovative systems, including comprehensive services.

Info SUPFINA

Schmelzegrün 7

D-77709 Wolfach

Tel. +49 7834 866-0

Fax +49 7834 866-200

Product Overview

Superfinish – Attachments

Tape- and stone-finishing attachments for mounting on carrier machines

Manual operation, optionally with programmable control units

Integration in CNC-processing machines possible

Dry and wet finishing

Spherical finishing attachments for flat or spherical surfaces

Supfina LeanCostMachine

Flexible superfinishing machine for small batches

Up to six attachments can be installed

Different workpiece-clamping systems

Portable or fixed control panel

Customized setup options

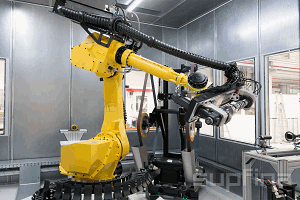

Supfina R-Cell

Flexible robot cell with component manipulation by robots

Finishing, deburring and brushing

Compact cell design

Ideal as a replacement for complex manual processes

Simple control concept

Supfina Spiro

Fine grinding with proven Supfina precision

High-performance operation

Reduced tool wear due to low vibration machine concept

User-friendly, intuitive operation

High degree of automation possible

Supfina Planet BD

Grinding of coated brake discs

Double side process

Coating- grinding automatizated as a complete solution

In-process measurement

Supfina long therm experience

Supfina Planet V

Double-disk grinding, the new dimension!

Modern, compact design

For mass and precision flat components

Selective grinding methods

Flexible automation capability

Supfina Nano

Plane finishing with new perfection

Compact machine concept for machining flat and sealing surfaces

Use of conventional and superabrasive tools

Mobile, flexible in-process measuring system

Universal loading and unloading

Supfina Face

Multi-stage vertical spindle assembly

Bridge design for maximum stability

Fast setup processes

Supfina IQ-Finish process control

High degree of automation

Supfina Speedfinish

Faster fine grinding

Higher material removal

Dry processing

Process reliability

High efficiency

Supfina Cenflex 1

Superfinishing of crankshafts, camshafts, transmission shafts, and balancer shafts

Up to 15 superfinishing units can be assembled

Automatic device adjustment

Also suitable for very small series in prototype construction

Series production in flexible production lines

Supfina Cenflex 2

Superfinishing of crankshafts, camshafts, transmission shafts, and balancer shafts

Up to 23 superfinishing units can be assembled

Automatic device adjustment

Economical adaptation to new workpieces

Suitable for small series to large series production

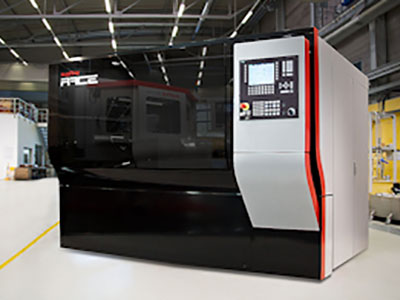

Supfina Race

Superfinishing of ball bearings/roller bearings inner and outer rings

Multi-stage, automated operation

Stone and tape finishing can be combined

Modern controller with integrated technology memory

Minimal downtime

Supfina RaceFlex

Superfinishing of ball and roller bearings

Highly flexible raceway finishing machine

4 superfinish units

Machining of inner and outer rings

High cost-benefit factor

Supfina MultiFlex

Superfinishing of steering and gear racks

Modular machine design

Up to two individually controlled superfinishing units

Short cycle times

High flexibility

Supfina MultiTool

Superfinishing of small shafts with stone and/or tape

Integrated crane hooks

Universal and compact

Highest tool lifetime

Alternative use of tape and/or stone