Selected Products For Your Success

BRUDERER

Precision – Swiss made

BRUDERER offers high-precision and high-performance fully-automated stamping presses with press forces range from 180 up to 2500 kN, for stamping and forming both simple and complex parts.

The company distributes its products to customers around the world in various sectors,

including the automotive, electrical, electronics, watch and medical industries as well as the

food and beverage sector.

Servo, roller and gripper feeds are part of the broad range of products which the company provides, as well as peripheral equipment of well-known manufacturers.

The comprehensive offer is complemented by a range of services including control technology, overhauling and training.

Founded in 1943, the family-run company has its production location in Frasnacht(Switzerland).

BRUDERER offers a world wide service with its subsidiaries around the globe.

Info BRUDERER

BRUDERER AG

Egnacherstraße 44

9320 Frasnacht

SCHWEIZ

Tel. +41 71 447 750-0

Product Overview

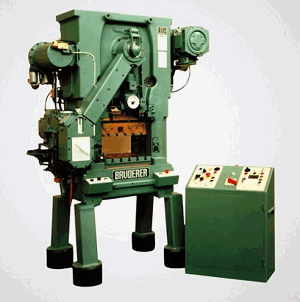

BRUDERER Stamping presses

In the steel metal, stamping and forming industry, BRUDERER stamping presses are synonymous for maximum performance, utmost precision and unsurpassed reliability. Our BSTA range inlcudes high-performance stamping presses with press forces from 180 up to 2500 kN and a stroke speed range of 100 to 2000 spm.

The unique lever system of the BSTA stamping press distributes the load acting on the ram in the system. The load distribution, the minimal bearing clearance and the efficient lubrication system are the main reasons for the long life and consistently high precision of the BRUDERER high-performance stamping presses.

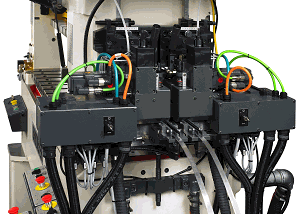

BRUDERER Feed units

The feed units developed by BRUDERER allow for the highest possible accuracy, even for complex production processes. Mechanically or electrically driven versions, suitable for different raw materials.

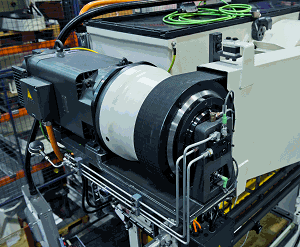

BPG planetary gear

The 2 in 1 solution from BRUDERER – tool test press and stamping machine. With the planetary gear, the speed is freely selectable from one stroke per minute. Even at minimum speed, you work with 100% power.

BRUDERER BSA servo axis technology

BRUDERER’s new servo axis technology is setting new standards in terms of servo drive technology for stamping processes. It combines the advantages of servo axes over mechanical drives with the benets

of the fully integrated technology of experienced manufacturers across the entire stamping process, providing more exibility and efficiency and a whole host of new possibilities within the production

chain and in tool manufacturing.

BRUDERER Controls

BRUDERER control systems provide clarity and the highest leveol of control over all process cycles. They are simple and intuitive to operate and allow entering and changing of data during the production process. The ram axis can be corrected manually or automatically – during the production process and to the narrowest of tolerances of maximum process reliability. Factory-set or user-dened retooling sequences provide support during retooling and prevent erroneous operator intervention.

BRUDERER Overhauling

A retrofit can be an attractive alternative to a new stamping press. There is often more potential in a used machine than you think. By replacing outdated components and adding new, current technologies, existing machines are brought up to date and can achieve performance levels matching those of a new machine. One of the possibilities is, for example, an extended tool loading area.